Products

Our Contributions

Industries We Serve!

This can be a short description about a project or an industry you are contributing to through the reliable products you build.

Quality Comes First! We Make Sure That Every Minute Detail Is Looked Into While Manufacturing Even The Smallest Product. Our Focus Is 100% On Client Needs And Satisfaction.

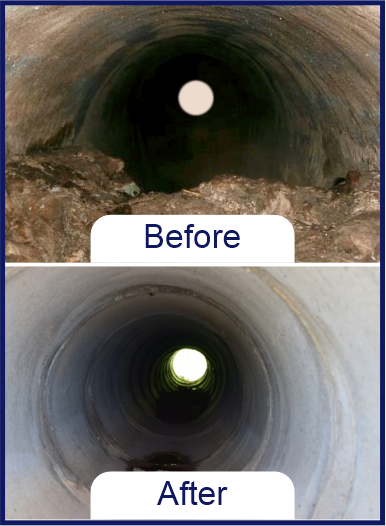

1. Industrial drain cleaning

How it works

To remove blockage and obstructions from drain, N Cube Construction employs the latest trenchless technology.

With trenchless technology, it’s possible to provide a thorough industrial drain cleaning by digging just one access hole, rather than uprooting an entire stretch of earth to dig a trench for accessing drains. This technology saves time, money and preserves any valuable landscaping that may be in place above your sewer lines and drains.

Once the access hole has been dug, N Cube Construction boasts a full fleet of the vehicles and tools needed for a thorough, effective industrial drain cleaning. From high-pressure water jets to mechanical augers that can cut away blockages, N Cube Construction has everything necessary to clean your industrial drains as thoroughly as possible.

2. Trenchless Solutions

How it Works

The set of works involves activities or techniques for making holes or conduit for underground activity without disturbing the surface. It is a guided trenchless method for underground pipelines installations. This trenchless method is ideal for the installation of cables and ducts, water mains, pumped sewer lines, gas lines and oil lines.

- Horizontal directional drilling (HDD)

- Mini HDD

THE PROCESS

- For execution pit is to be excavated after that machine is lowered and installed in bore pit.

- The pilot borehole is drilled on fixed path.

- The borehole is drilled of desired size by changing rig/drilling bit and borehole will be washed if needed.

- After washing of hole pipe is carried away in that hole.

3. Precast concrete products

Precast concrete is created off-site by using a mould. That’s the main difference between precast concrete and site cast concrete. Here is a simplified overview of the precast concrete process

- Precast concrete is poured into a wooden or steel mould with wire mesh or rebar. This mould may also have prestressed cable, if needed.

- It is cured in a controlled environment at plant itself.

- Once finished, the precast concrete is transported to a construction site and put into place.

This process is faster, safer and affordable than standard concrete.

Hereby, we have listed some of our products.

- Precast RCC Drain Works

- RCC Louvers & Fins

- Cable Trench Tiles (With & Without Reinforcement)

- Route Markers

- Precast RCC Sleepers

- Pre-stressed Concrete Items

- RCC Blocks

- RCC Wall

- Precast RCC Hand Hole & Man Hole

- RCC Cover Slabs for Various applications, etc.